Intel’s Cutting-Edge US Semiconductor Tech to be Produced in Chandler Plant

So, Intel’s doubling down on US manufacturing, huh? The news that their cutting-edge semiconductor technology is heading to the Chandler, Arizona plant is more than just a press release it’s a sign of bigger things to come. Here’s the thing: it’s not just about making chips. It’s about securing the future of technology, and frankly, national security itself. As someone who’s been tracking the semiconductor industry for years, let me tell you why this move is a total game-changer. I’m going to focus on the ‘Why’ angle.

Why Chandler? The Strategic Play

Why Chandler, specifically? It’s not just some random pin on the map. Arizona has been quietly building itself into a semiconductor hub for decades. The infrastructure is already there, and there is an existing skilled workforce. Intel already has a significant presence in Chandler, so expanding there makes logistical sense. It’s about leveraging existing resources and building on established strengths. It’s also worth mentioning the favorable tax incentives the state offers – a factor no company can ignore. Think of it like this: it’s not just about the cost of building a factory; it’s about the entire ecosystem that supports it. The proximity to other key players in the tech industry also streamlines collaboration and innovation in semiconductor manufacturing .

The Bigger Picture | Reshoring and Security

But, let’s be honest, there’s more to it than just cost savings. This move is deeply tied to the global shift towards reshoring critical industries. For years, the US has relied heavily on overseas manufacturers for its semiconductors . That reliance became a glaring vulnerability when supply chains got snarled during the pandemic. Suddenly, everyone realized that depending on foreign entities for something as crucial as semiconductor chips was not a sustainable strategy. Now, governments are actively incentivizing companies to bring manufacturing back home. This isn’t just about economics; it’s about national security. A domestic semiconductor supply chain ensures that the US isn’t held hostage by geopolitical tensions or disruptions. I initially thought this was straightforward, but then I realized the scale of the geopolitical implications!

Technological Advancement and Innovation

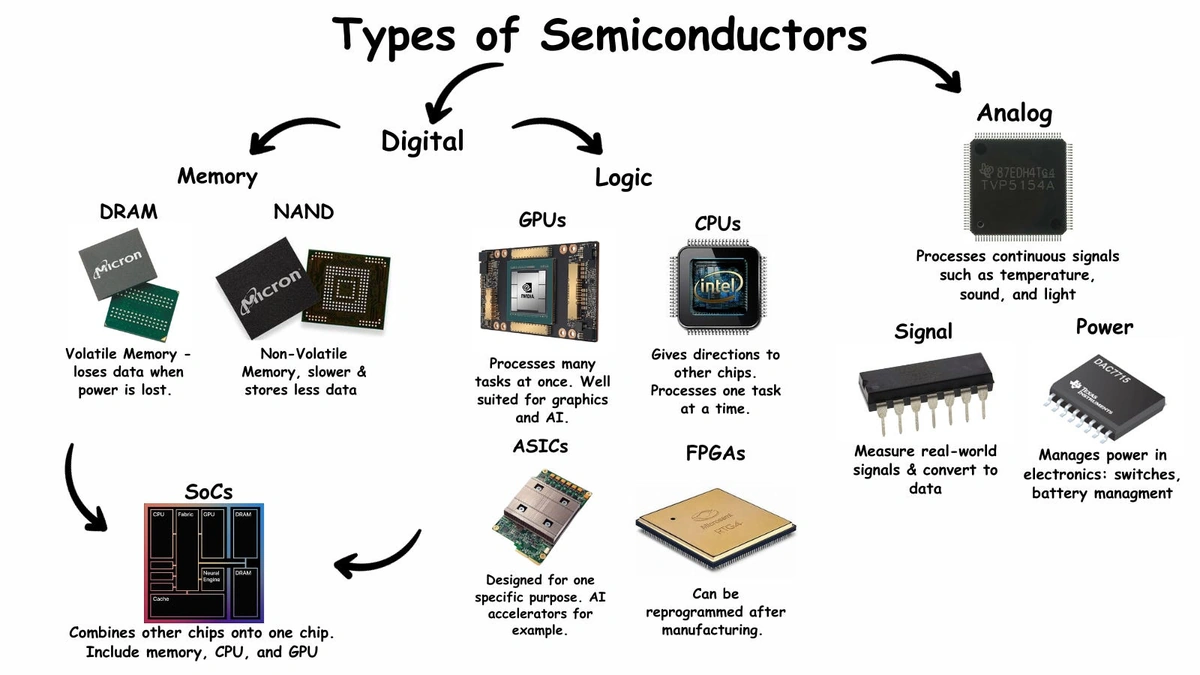

What fascinates me is the kind of technology we’re talking about. Intel isn’t just moving any old production line to Chandler; they’re bringing their cutting-edge technology – the kind that will power the next generation of devices. We’re talking about advanced semiconductor technology nodes, the building blocks of everything from smartphones to AI supercomputers. This means the Chandler plant will be at the forefront of innovation. This brings high-paying jobs to the US and stimulates the entire local economy. Beyond the immediate economic benefits, having this kind of advanced manufacturing onshore fosters a culture of innovation. It creates a virtuous cycle where research, development, and manufacturing reinforce each other. The ripple effect can be immense, leading to new breakthroughs and entirely new industries.

The Impact on India | Opportunities and Challenges

And what does this mean for India? Well, India is also making big moves in the semiconductor space. The government has launched incentive programs to attract investment and develop a local semiconductor ecosystem . Intel’s move in the US, while seemingly distant, has implications. It sets a high bar for technology and innovation. India needs to compete not just on cost but also on technological capabilities. This means investing heavily in R&D, developing a skilled workforce, and fostering collaborations between industry and academia. This is a golden opportunity for Indian engineers and researchers to learn and contribute to this rapidly evolving field. It also presents a challenge – the need to create a competitive environment that can attract global players and foster local innovation. We have to make sure we invest in relevant semiconductor equipment . And , AI is going to be huge!

Challenges Ahead and Future Outlook

Of course, it’s not all sunshine and roses. Building and operating a cutting-edge semiconductor plant is incredibly complex and expensive. There are technical challenges, supply chain hurdles, and the ever-present need to stay ahead of the competition. And the competition is fierce. Companies worldwide are investing heavily in semiconductor technology , and the pace of innovation is relentless. Intel needs to execute flawlessly to maintain its leadership position. What I realized is that the long-term success of this venture depends on a combination of factors – technological prowess, strategic partnerships, and supportive government policies. While sources suggest a positive outlook for the industry, the official confirmation is still pending. It’s best to keep checking the official portal.

FAQ

Frequently Asked Questions

What exactly does ‘cutting-edge’ mean in terms of semiconductor technology?

It refers to the smallest feature size (measured in nanometers) on the chip. Smaller features mean more transistors can be packed onto a single chip, leading to greater performance and energy efficiency.

How long will it take for the Chandler plant to be fully operational?

Building a semiconductor plant is a multi-year project. It typically takes 2-3 years to construct the facility and another year or so to ramp up production.

Will this move lower the cost of electronics for consumers?

Potentially, but not immediately. Reshoring manufacturing can reduce supply chain risks and potentially lower long-term costs, but the initial investment is significant. There is also the factor of advanced packaging to consider.

How can I get involved in the semiconductor industry?

A background in engineering, physics, or material science is a good starting point. Look for internships and entry-level positions at semiconductor companies. Also, consider advanced degrees focused on microelectronics and nano fabrication. Check out our other articles on Intel .

What are the key materials used in semiconductor fabrication?

Silicon is the primary material, but other elements like germanium, gallium arsenide, and various rare earth elements are also used. The purity and quality of these materials are critical.

What role does semiconductor equipment play in all of this?

Semiconductor equipment refers to the highly specialized machinery used to manufacture semiconductor chips . This includes lithography systems, etching machines, deposition equipment, and testing equipment.

Ultimately, Intel’s decision to produce its cutting-edge semiconductor technology in Chandler is a strategic move with far-reaching implications. It’s a win for US manufacturing, a boost for national security, and a step towards a more resilient global supply chain. It’s also a reminder that the semiconductor industry is at the heart of the modern world, and its future will be shaped by innovation, investment, and strategic foresight.